Drive Efficiency: Upgrading Your Building Machinery with Premium Komatsu Undercarriage Parts

Drive Efficiency: Upgrading Your Building Machinery with Premium Komatsu Undercarriage Parts

Blog Article

Effective Solutions: Undercarriage Parts for Heavy Machinery

When it comes to hefty equipment, the undercarriage is a crucial part that frequently determines the total effectiveness and performance of the equipment. Quality undercarriage components play a substantial function in making sure the smooth operation and long life of heavy equipment. From excavators to dozers, each tool counts heavily on its undercarriage to withstand hard working problems. Wear and tear are inevitable, leading to prospective issues that can prevent efficiency and rise maintenance prices. In this discussion, we will certainly check out the relevance of buying excellent undercarriage parts, usual wear challenges encountered by heavy equipment operators, the benefits of prompt substitutes, guidelines for selecting trustworthy suppliers, and necessary upkeep suggestions to expand the lifespan of undercarriage elements.

Relevance of Top Quality Undercarriage Components

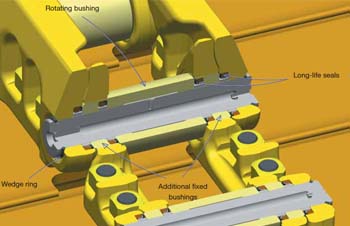

Quality undercarriage parts are vital components in making sure the longevity and efficiency of hefty machinery. The undercarriage of tools such as excavators, bulldozers, and track loaders plays a vital duty in sustaining the maker's weight, giving stability on numerous surfaces, and absorbing the effect of irregular surfaces. By investing in high-quality undercarriage parts, drivers can significantly extend the lifespan of their machinery and minimize the danger of unforeseen malfunctions.

One secret benefit of utilizing top quality undercarriage parts is the improvement of total machine efficiency. Long lasting tracks, sprockets, idlers, and rollers minimize rubbing and guarantee smoother movement, ultimately resulting in raised productivity and efficiency on work websites. Furthermore, trustworthy undercarriage parts lessen downtime for upkeep and repair work, allowing drivers to optimize their functional hours and project target dates.

Typical Undercarriage Wear Problems

Benefits of Timely Substitute

One secret benefit of timely undercarriage part replacement is increased machine uptime. By changing used parts before they fail, the risk of unexpected breakdowns is minimized, reducing downtime for fixings and upkeep. This aggressive strategy not just keeps the hefty equipment operational click here for info but also prevents potential damages to other components that can result from a failing undercarriage.

Additionally, replacing undercarriage parts promptly Web Site can enhance total productivity. A well-maintained undercarriage ensures optimal device performance, permitting for smoother procedure and greater effectiveness in completing jobs. This, consequently, leads to boosted job website efficiency and cost financial savings by avoiding disturbances and hold-ups brought on by underperforming equipment. Investing in prompt undercarriage part substitute is a proactive technique that pays off in terms of boosted efficiency and minimized operational expenses.

Selecting the Right Undercarriage Distributor

Selecting the suitable undercarriage provider is a crucial decision that dramatically influences the performance and maintenance of heavy machinery. When choosing a distributor for undercarriage components, numerous factors should be taken into consideration to make certain optimal effectiveness and cost-effectiveness. To start with, it is vital to assess the provider's credibility and experience in the market. A respectable vendor with years of experience is most likely to give high-grade components and dependable service. Furthermore, take into consideration the range of products offered by the distributor. A provider that provides a large choice of undercarriage parts for various hefty machinery brands and models can be advantageous as it gives extra choices to satisfy specific requirements.

Balancing integrity, top my review here quality, and cost-effectiveness is key when selecting the appropriate undercarriage provider for hefty equipment. By very carefully examining these elements, you can pick a supplier that satisfies your demands and adds to the effective efficiency and upkeep of your heavy machinery.

Upkeep Tips for Extended Life Expectancy

To make certain an extended life expectancy for hefty equipment undercarriage components, implementing a proactive maintenance regimen is essential. Investing in quality undercarriage parts from credible distributors is just as important for guaranteeing long life. By adhering to these upkeep pointers faithfully, hefty equipment proprietors can maximize the efficiency and longevity of their undercarriage components, eventually lowering downtime and operational expenses.

Final Thought

In conclusion, top quality undercarriage parts are essential for the reliable operation of hefty machinery. Selecting a reliable distributor and complying with correct maintenance techniques are crucial to ensuring the expanded lifespan of undercarriage parts.

Excessive wear and tear on undercarriage components of hefty machinery can lead to significant functional obstacles and raised upkeep expenses. Regular inspections, correct upkeep, and timely substitutes of worn undercarriage parts are essential to alleviate these typical wear problems and guarantee the optimal performance of heavy machinery.

A distributor that uses a wide option of undercarriage parts for different heavy equipment brands and versions can be helpful as it offers extra choices to meet details requirements.

By adhering to these upkeep pointers diligently, heavy machinery owners can maximize the efficiency and longevity of their undercarriage parts, eventually minimizing downtime and functional expenses.

Report this page